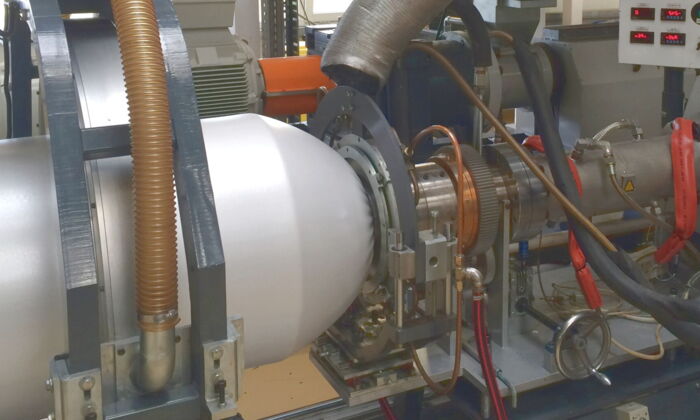

The Promix annular die for foam extrusion enables the production of high-quality foamed films made of PP, PS, PE, PET and biopolymers.

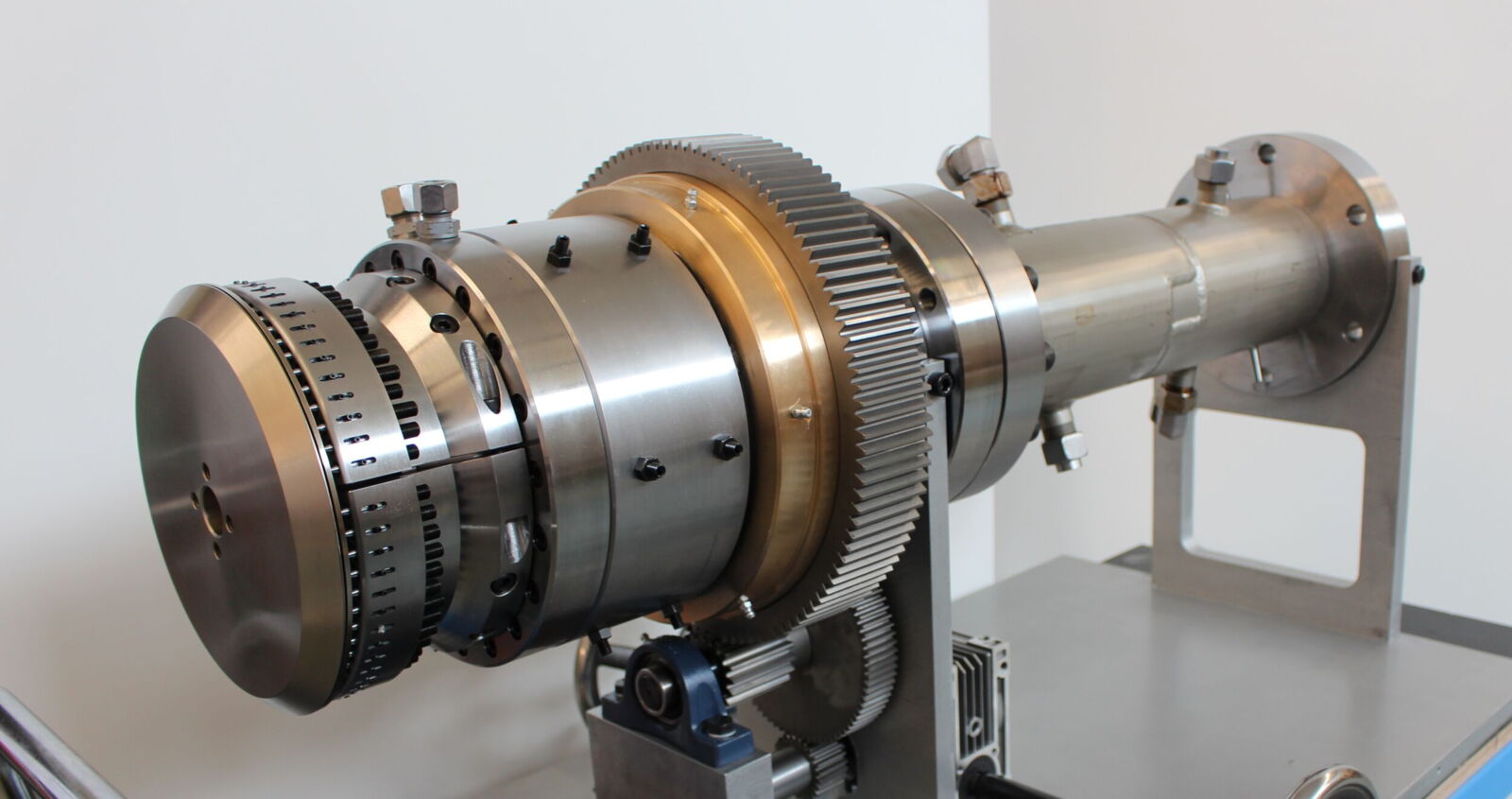

Technology Promix Annular Die

Die technology has a decisive influence on the quality of EPS (XPS), XPE, XPP, XPET foamed films. The Promix annular die technology combines 20 years of experience in foam die design and sets new standards in the production of foam films. Thanks to the special patented die design, foam density and film thickness tolerances can be further reduced.

This leads to high material and cost savings. The flex-lip concept allows very precise adjustment of the film thickness. This does not change when the die is opened and closed, which eliminates the need for time-consuming readjustment.

Universally applicable

Today, flexibility is in demand! Triggered by the environmental discussion, the requirements for raw materials and manufactured products are changing rapidly. Promix annular dies are very flexible and can easily be adapted to different raw materials, throughputs, film widths, film thicknesses and foam densities. Contact us to test a Promix ring die for your application.

Your advantages

- Very uniform fine-cell foam structure

- Reduction of foam density

- Very narrow thickness tolerances

- Independent of material and operating point

- Simple, safe and reproducible die lip adjustment