Promix specializes in demanding cooling and heat exchanger tasks. These include the cooling of viscous media or media that are sensitive to degradation.

Melt cooler and heat exchanger – the challenge

Due to the increase in viscosity caused during cooling, the fluids to be cooled tend to adhere and form deposits on the cooling surfaces. This leads to long residence times and product degradation (fouling). Since the introduction of Promix P1 cooling mixer technology, these problems are a thing of the past. The cooling mixer technology, which was developed using state-of-the-art CFD methods, is now being used in more and more areas of application.

The technology, which was originally developed for plastics processing, is now also being used successfully in fiber and polymer production, chemical, pharmaceutical, and food production. In addition to cooling, the technology is also well suited for heating fluids that are residence time critical and sensitive to decomposition.

Promix Melt Coolers and Heat Exchangers improve your process

- Very high cooling capacity and precise temperature control of the melt at the outlet

- No deposits and decomposition thanks to optimum flow profile

- Narrow residence time spectrum

- Short installation length

- Low pressure drop

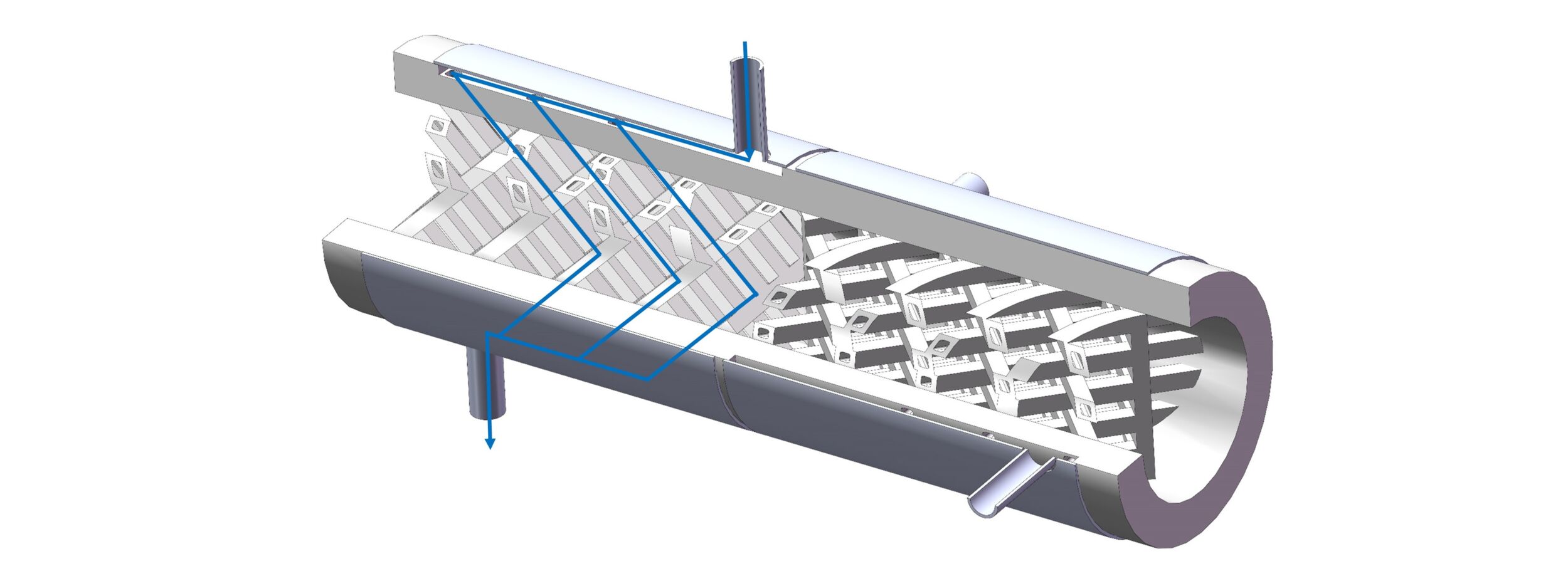

P1 Cooling Mixer Technology

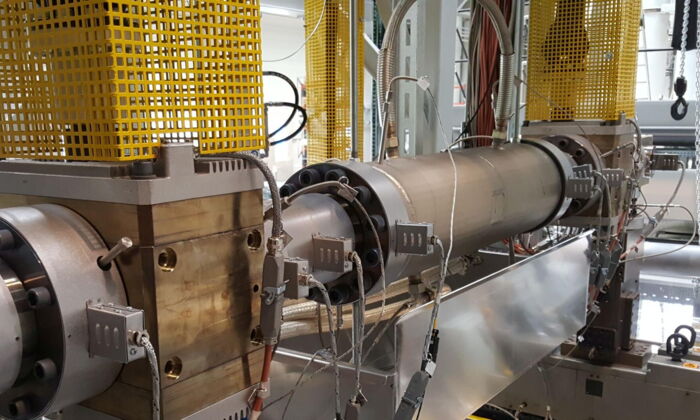

The Promix P1 cooling mixer is the unique combination of a very efficient static mixer and a powerful cooler. The novel patented technology opens up completely new process engineering possibilities when cooling plastic melts and other viscous fluids. The simultaneous mixing and cooling processes in the P1 allow very efficient cooling close to the solidification point

of the melt without the formation of deposits or the risk of "freezing". The melt temperature is simultaneously homogenized over the entire cross-section. Depending on the process step, the ideal melt temperature can thus be precisely set and kept constant over time.

Technical article A cool mix

Your advantages

- Very efficient cooling of polymer melts and other viscous fluids close to the solidification point

- Insensitive to deposits and "freezing

- Precise temperature control and uniform temperature distribution at the outlet

- Very robust construction insensitive to pressure loss

- Extremely gentle cooling and heating of residence time critical fluids

- Unique self-cleaning behavior, for example during color changes

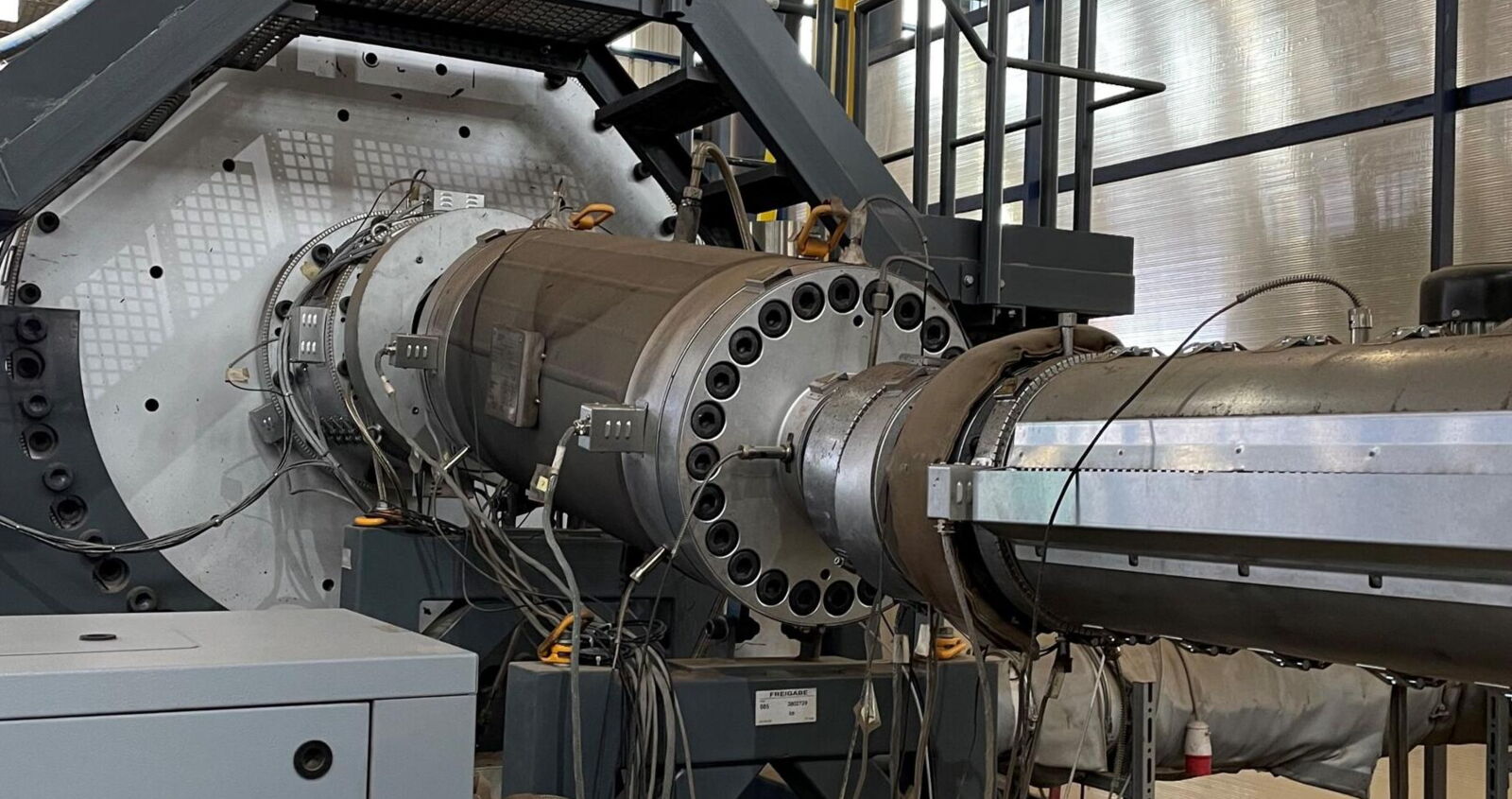

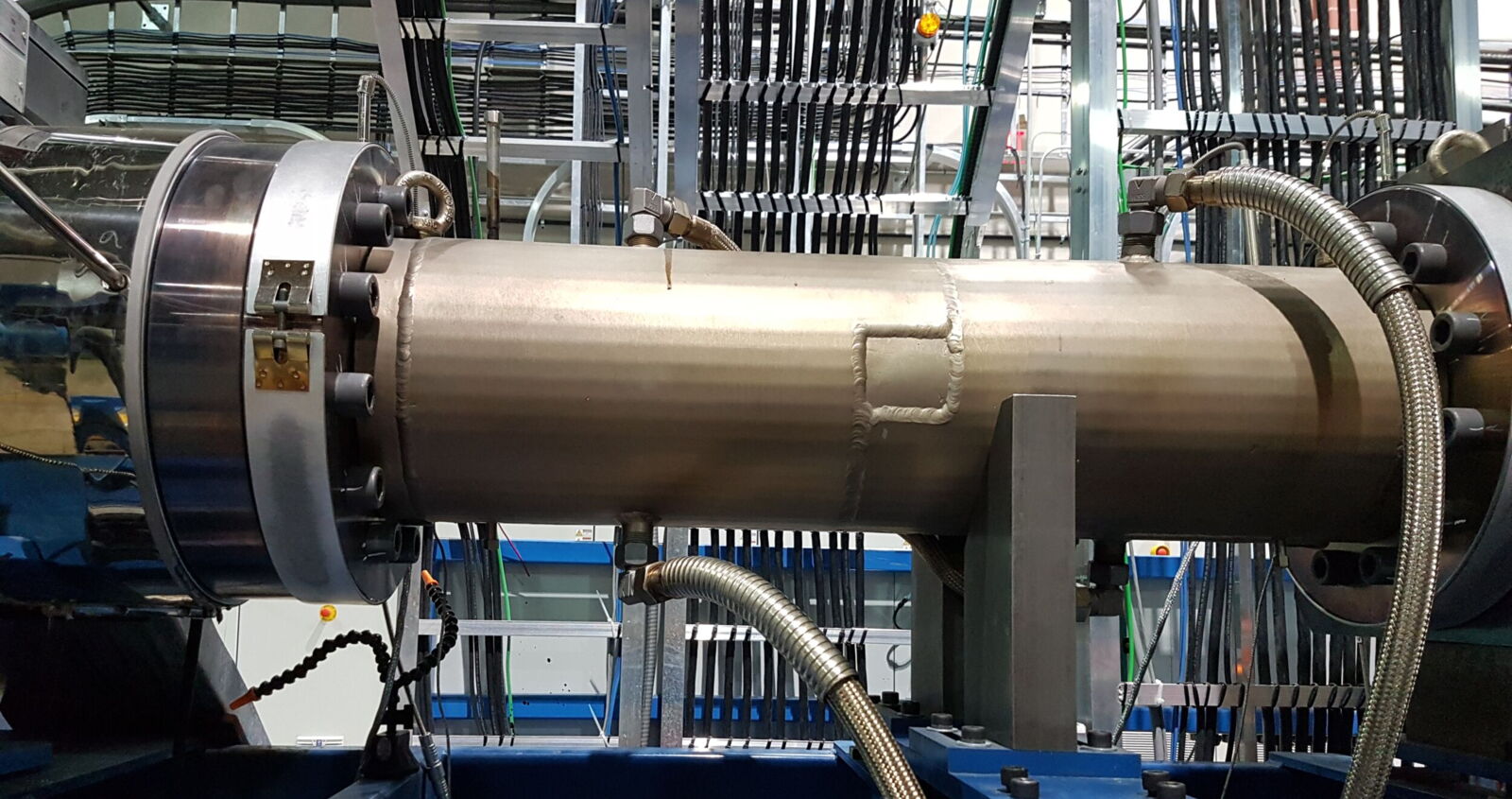

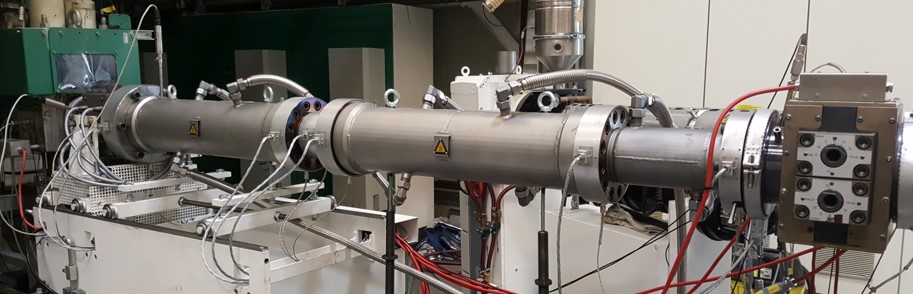

From the laboratory to production

The Promix P1 cooling mixer technology is available in a wide range of sizes and designs. These include heat exchangers for laboratory applications with a throughput of 5 kg/h as well as industrial high-performance coolers with throughputs of > 10'000 kg/h. The special design of the P1 cooling mixer allows reliable and safe scaling of results from pilot tests to industrial scale. This is a decisive advantage especially when designing heat exchangers for new applications.